High value-added products by using state-of-the-art technologies

Osmo Protection Technology

Osmo Protection Technology (TOP) promotes high metabolic and physiological performance of the microorganisms that are part of the inoculant

TOP improves the physiological state, survival rate, and concentration of bacteria both in the package and once the seed is treated. This technology also improves stress tolerance, especially when the inoculant is used with chemical seed treatments or under moisture-limited conditions.

This technology allows efficient nodulation and Biological Nitrogen Fixation, even under adverse conditions, such as high temperatures and drought, that may affect the survival of the microorganisms. Climate change is increasing the frequency of stressful events during the early stages of the crop. In this context, a resilient inoculant becomes a valuable tool to optimize production levels.

Main Benefits:

- Formulas that are environmentally friendly and safe for workers.

- Enhance performance of herbicides, fungicides, insecticides and foliar fertilizers

- Ensure accuracy in application to targeted areas.

- Long shelf life – with improved germination and emergence uniformity

- Improves crop resistance in abiotic stressful situations, especially low temperatures, water shortages, and soil acidity.

Bio-inducer technology

Bio-inducers is a new and pioneering concept in the field of agricultural microbiology. They open a gateway to the world of chemical signaling between plants and microorganisms. Bio-inducers trigger molecular signaling early on in the metabolic processes between bacteria and plants, which allows early nodulation..

In other words, in the manufacturing process, bacteria have been prepared to recognize and respond immediately to specific chemical signals produced by the legumes. This state-of-the-art technology encourages the symbiotic partnering of plants and bacteria. It stimulates interaction with other beneficial soil microorganisms. Bio-induction also promotes growth of legumes as a result of a greater activity in the rhizosphere and more effective nodulation.

Main Benefits:

- Promotes a more effective and earlier nodulation: more nodules located on the main root, where they fix more nitrogen.

- Maximizes the Biological Nitrogen Fixation (BNF).

- Increases disease tolerance due to signal activation.

- Activates microbial and plant physiology.

LLI Technology- Long Life Inoculant

With specially designed inoculant formulations and sophisticated application methods, seed companies are able to treat seed in direct combination with fungicides, insecticides, micronutrients, and polymers. Enhancing the inoculant with a long-life formuation achieves extended on-seed rhizobia survival time, providing growers with a high-quality, yet simple solution.

Long Life Inoculant (LLI) Technology in soybeans allows treatment for 220 days before seeding, even when mixed with fungicides and herbicides. The exact time frame is directly influenced by the chemicals combined and storage conditions of the treated seed.

This cutting-edge technology becomes a powerful ally to the seed industry, allowing ready-to-use seeds with superior quality, in terms of product distribution, dust-off control, and flow.

Main Benefits:

- Helps to achieve a more efficient and sustainable production system.

- Saves substantial time and effort during planting operations.

- Ensures the quality of the treatment.

- Improves germination and emergence uniformity.

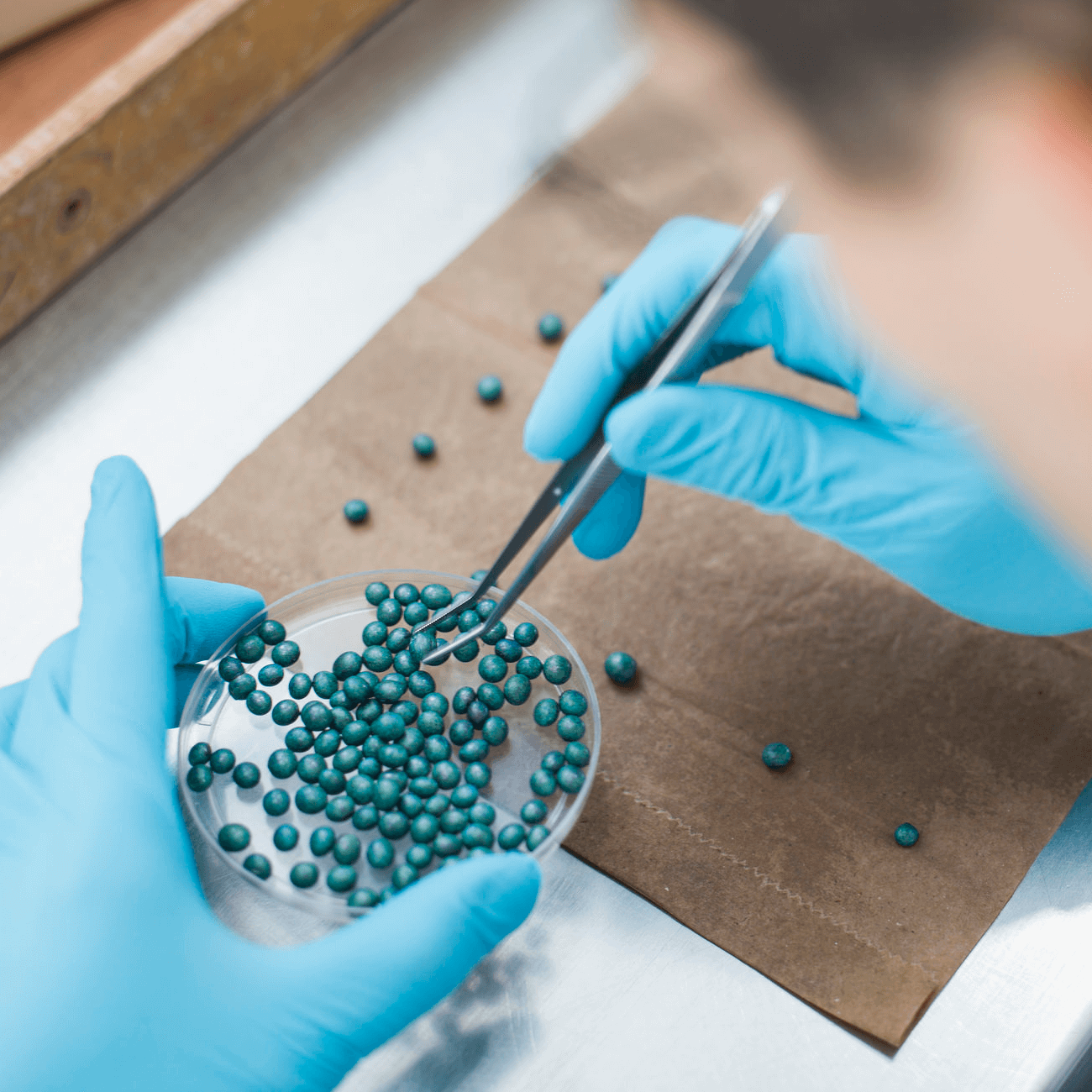

High Concentration (HC) Technology

Rizobacter presents its new formulation of Higher Concentration (HC) inoculants based on specially selected bacterium that make the seed treatment process more efficient.

This new generation of inoculants aims to reduce the application rate, improve the interaction with other technologies in the seed treatment, and maximize nodulation and Biological Nitrogen Fixation (BNF). Moreover, it is compatible with many common seed treatments, making application more convenient, and so prevents issues at planting time.

Main Benefits:

- Greater concentration of bacteria and greater stability in the container.

- Lower application rate.

- Bacteria are more physiologically active compared to traditional production methods.

- Superior protection at the cell membrane level to reduce desiccation.

- Greater survival on the seed surface.

- Better adaptability to adverse environmental conditions such as moisture and chemical stress.

We evaluate quality in every detail

To ensure the efficiency of our inoculants we:

Carry out quality tests to guarantee the efficiency of our inoculants.

-

1.

Count our microorganisms by measuring how many of them go to the seed with the inoculant.

-

2.

Evaluate nodules by counting how many nodules are on the root of our soybean plant and other legumes. We also observe the positioning of the nodules and thanks to our technology we are able to have increased nodule counts on the primary root of the plant. This ensures a more effective nutrient transfer and energy utilization in the development of the crop.

-

3.

Measure the nodular dry mass. The number of nodules is important; however, mass is a vital criteria. With greater mass, the development of Biological Fixation of Nitrogen is very effective.

How are the nodules formed?

The inoculation of seeds is a biotechnological process by which two different types of living creatures come together: a microsymbiont (rhizobium) and a macrosymbiont (seed of a legume plant). After the union, the common structure developed is called the nodule. It is there where the beneficiary processes for both parts take place.

Related products